Protecting Building Occupants from Exposure to Biological Threats

Introduction

Most commercial buildings are not configured and maintained in ways that effectively reduce occupants’ risk of exposure to biological threats. As a result, the majority of people in high occupancy buildings are unnecessarily vulnerable to both aerosolized biological attacks and naturally occurring biological threats. Note: All references cited below can be found in the reference list.

Types of Biological Threats

Intentional threats—bioterrorism: Bioterrorism is an urgent and growing threat to U.S. national security, and the lethality of biological weapons mirrors that of nuclear weapons. A covert biological attack on U.S. civilians could potentially cause tens of thousands of casualties and immense social and economic disruption. Furthermore, there are no significant technical barriers to prevent the development and use of biological weapons, and tactical warning of a biological attack is unlikely.

Several states potentially hostile to the United States are suspected of having biological weapons programs, and there are groups, such as al-Qa’ida, that are both committed to attacking the U.S. and are pursuing biological weapons capabilities. 2,47 According to the July 2007 U.S. National Intelligence Estimate regarding the terrorist threat to the U.S. homeland, al-Qa’ida “would not hesitate” to use biological weapons “if it develops what it deems is sufficient capability.”2

Commercial buildings are attractive targets for biological attacks because they present a potential for wide-scale agent dispersal through air handling systems, as well as the potential to cause mass casualties and great economic loss, as a result of productivity losses, decontamination costs, etc.3,4 It is known that al-Qa’ida is aware of the potential to use air handling systems to attack building occupants: as early as 1998, training in Afghanistan-based al-Qa’ida camps included the use of ventilation systems as a "delivery system" to attack buildings with poisons.5

Naturally occurring threats—bacteria, molds, allergens, etc: Building occupants face threats from numerous, naturally occurring biological contaminants that can be spread through the air, including viruses, bacteria, molds, toxins produced by bacteria/molds, and allergens such as pollen, pet dander, and pest droppings.6-13 The health effects associated with naturally occurring indoor biological air pollutants include disease, toxicoses, and hypersensitivity (i.e., allergic) diseases.6-13 In addition, exposure to indoor biological air pollutants has been associated with "sick building syndrome," a set of non-specific symptoms that may include upper-respiratory irritative symptoms, headaches, fatigue, and rash, and "appear to be linked to time spent in a building, but no specific illness or cause can be identified.”14

Indoor biological pollutants can find their way into and spread around buildings in varying ways depending on the contaminant. Many bacteria, molds, and allergens are ubiquitous in the outdoor environment and can enter a building and spread throughout via the air handling system.6 Bacteria, molds, and allergens also can be brought into a building on myriad sources, including building materials, carpets, clothing, food, or by pets and pests (e.g., rodents, cockroaches).6 Once in a building, certain bacterial and mold species can get into the HVAC system and grow in damp or wet places such as cooling coils, humidifiers, condensate pans, and filters, or may grow in places where water has collected, such as ceiling tiles, carpeting, or insulation, any of which can then serve as a continued source of contamination throughout a building.6

Inadequate Protection for Most Buildings

Problems in configuration and maintenance: Most commercial buildings are not configured and maintained in ways that effectively reduce occupants' risk of exposure to biological threats:

- The HVAC systems of most commercial buildings do not have air filtration systems sufficient to effectively remove biological contaminants from the air; this is particularly true for bacteria and viruses.

- Filters are frequently installed improperly and/or maintained improperly, resulting in reduced filtration efficiency as a result of filter bypass

- Many commercial buildings have infiltration problems that can reduce the effectiveness of air filtration systems because air that enters a building via infiltration bypasses filtration systems

- Many commercial buildings have outdoor air intakes located at or near ground level, making them more accessible; this increases occupants' vulnerability to biological attacks and also can increase vulnerability to naturally occurring threats when the air intake is near a potential contamination source.3,4,15,16

Expert Recommendations for Building Owners

On June 13–14, 2005, the Center for Biosecurity of UPMC convened the Working Group on Reduction of Exposure to Infectious Agents during a Covert Bioterrorism Attack. The Working Group was charged with recommending practical steps that building owners can take to reduce the risk of occupant exposure to harmful pathogens after an aerosol release of a biological weapon.1 The Working Group was composed of subject matter experts in air filtration, building ventilation and pressurization, air conditioning and air distribution, biosecurity, building design and operation, building decontamination and restoration, economics, medicine, public health, and public policy.

Practical measures and available technologies: The Working Group focused on developing practical recommendations for improving or adjusting the functions of the heating, ventilation, and air conditioning (HVAC) systems in commercial and public buildings that could reduce the risk of occupant exposure to aerosolized pathogens following a biological attack. The Working Group placed an emphasis on currently available technologies that would not be prohibitively expensive or require major retrofits and that could provide additional benefits, such as improved indoor air quality.

A caveat — do no harm: It is imperative that building owners and operators fully assess the potential consequences of any risk reduction measures prior to implementation. Changes should not be made to buildings, building systems, and operations if they will degrade indoor air quality and comfort under normal operating conditions or if they will in any way interfere with the proper operation of fire protection and life safety systems.

Seven recommendations for immediate implementation: The following recommendations can be immediately implemented by building owners and operators, as appropriate; they are based on those of the Working Group on Reduction of Exposure to Infectious Agents during a Covert Bioterrorism Attack.

- Minimize filter bypass: Seal, caulk, and gasket everything (filter cartridge, retainer bank, tracking, etc.) to minimize filter bypass.

- Commission: Commission buildings during design and construction, and re-commission routinely to ensure that ventilation systems are operating in line with design intent.

- Enhance filtration efficiency: Increase air filtration to the maximum economically justifiable MERV level to improve the removal of particulate matter from the air.

- Maintain filter systems: Conduct regular inspections and maintain filter systems correctly to ensure that the HVAC system functions properly.

- Train staff: Ensure that maintenance staff has the appropriate training to operate and maintain the HVAC system.

- Tighten the envelope: When economically feasible, tighten the building envelope to reduce the infiltration rate.

- Pressurize: When economically feasible, pressurize the building to reduce infiltration rate.

Potential collateral benefits: Available scientific data suggest that implementing measures to reduce building vulnerability and the related risk of occupant exposure to bio threats may have additional (“dual-use”) benefits, including:

-

improved HVAC system cleanliness, which can potentially improve building energy efficiency and reduce operating/maintenance costs over time; and

-

improved indoor air quality, which may improve the health and increase the productivity of building occupants.15

Building Vulnerabilities

Most commercial buildings are not configured and maintained in ways that effectively reduce occupants’ risk of exposure to biological threats. Biological threats include both dangerous biological agents (e.g., anthrax) that may be intentionally introduced into a building (bioterrorism), and naturally occurring allergens, molds, and bacteria that are introduced into a building unintentionally or by natural processes. Because many commercial and public buildings are not configured and maintained in ways that effectively reduce their vulnerability to biological threats, the people who live, work, and shop in them are at risk of unnecessary exposure to intentional and naturally occurring biological threats, the effects of which may reduce productivity and cause illness, or even death.

Bioterrorism

Buildings are attractive targets for terrorists because the intentional release of an aerosolized biological agent in an inadequately protected commercial or public building offers the potential for wide-scale agent dispersal through the air handling system, which can cause mass casualties and high economic costs (i.e., productivity losses and decontamination costs).3,4

Four building attack scenarios: There are 4 general scenarios whereby a biological agent could be intentionally introduced into a mechanically ventilated building.3,15

- Large-scale outdoor release of a biological agent: In this scenario, some portion of an aerosolized biological agent released up-wind of a building would enter the building through the outside air intake and be distributed throughout by the HVAC system. In addition, the aerosolized biological agent could enter the building via infiltration, which is the passage of air into a building through leaks in the building envelope.

- Outdoor release of a biological agent directly into an air intake: In this scenario, a biological agent would be introduced directly into the HVAC system from outside of a building via the air intake, and then distributed throughout the building.

- Indoor release of a biological agent directly into an HVAC system: In this scenario, a biological agent would be introduced directly into the HVAC system from within the building and distributed throughout. Distribution and spread of the biological agent would depend on the HVAC system design and the agent's point of entry (e.g., air handling unit, supply air distribution system, return air distribution system).

- Indoor release of a biological agent in common area or special use space: In this scenario, an aerosolized biological agent would be released in a common area or special use space, such as a lobby, auditorium, or mail room. While such an attack would most directly affect the people present in the common area during the attack, some portion of the aerosolized biological agent could be distributed beyond the release area via airflows created by pressure relationships that exist within different parts of the building relative to each other. The biological agent also could be distributed beyond the release area as a result of its entry into HVAC system through the return air system (if present).

The likelihood of any of these 4 scenarios is impossible to determine and depends on the intentions and capabilities of a particular attacker relative to the existing level of vulnerability to the specific type of attack.20

Naturally Occurring Biological Threats

Sources: Sources of indoor biological pollutants vary depending on the contaminant.6 Many bacteria, molds, and allergens are ubiquitous in the outdoor environment and can enter a building through the air intake and spread throughout via the air handling system and/or infiltration. They also can be brought into a building on myriad sources including building materials, carpets, clothing, food, etc. or by pets and pests (e.g., rodents, cockroaches).

Certain bacteria and mold species that get into a building—through the air intake system, or infiltration, or carried by a vector—find their way into the HVAC system, where they can grow in damp or wet places, such as cooling coils, humidifiers, condensate pans, and filters, and then serve as a continued source of contamination throughout the building. Some bacteria and mold species can grow in places where water has collected, such as ceiling tiles, carpeting, and insulation, and serve as a continued source of contamination.

Bacteria and viruses that are spread by person-to-person transmission (e.g., mycobacterium tuberculosis, influenza virus) can be brought into a building by infected individuals, and potentially can enter the return air system and be spread throughout a building by the HVAC system. However, the extent to which HVAC systems contribute to the spread of such diseases is unclear. Additionally, indoor air conditions such as temperature and humidity, which are a direct result of an HVAC system’s conditioning of the air in the occupied space of a building, can affect the efficiency of person-to-person transmission of certain organisms, such as influenza virus.25 However, the extent to which indoor air conditions contribute to the spread of such diseases is unclear.

Potential adverse health effects of exposure; Building occupants can be affected and even sickened by numerous naturally occurring biological contaminants that can be spread through the air, including viruses, bacteria, molds, toxins produced by bacteria/molds, and allergens, such as pollen, pet dander, and pest droppings.6-13 There are several health effects associated with indoor biological air pollutants:

- Disease: Exposure to airborne bacteria, molds, and viruses can cause diseases such as legionellosis, pontiac fever, tuberculosis, histoplasmosis, aspergillosis, and influenza.

- Toxicoses: Exposure to airborne microbiological toxins (e.g., endotoxins, mycotoxins) can cause direct toxic effects. For example, humidifier fever—a flu-like illness—has been associated with exposure to microbiological toxins, although its etiology remains uncertain.

- Hypersensitivity (i.e., allergic) diseases: Exposure to airborne allergens such as pollens, pet dander, dust mites, fungi, and pest droppings can cause allergic diseases such as asthma, hay fever, and hypersensitivity pneumonitis.6-13

In addition, exposure to indoor biological air pollutants has been associated with "sick building syndrome," a set of non-specific symptoms that may include upper-respiratory irritative symptoms, headaches, fatigue, and rash, and "appear to be linked to time spent in a building, but no specific illness or cause can be identified.”14 The costs to the U.S. economy in performance losses as a result of sick building syndrome has been estimated at $76 billion.21

Poor indoor air quality was the 6th most common complaint among corporate tenants in 2003.22 It increases absentee rates and results in 2% to 4% performance losses on average.23 Furthermore, there have been several major lawsuits related to indoor air quality that have named builders, equipment manufacturers, and building owners as codefendants, and have resulted in multimillion-dollar settlements.[24

Inadequate Building Protection and Vulnerabilities to Biological Threats

The HVAC systems of most commercial buildings are not configured and maintained in ways that effectively reduce occupants' risk of exposure to biological threats.

Insufficient air filtration: The HVAC systems of most commercial buildings are not configured with air filtration systems that effectively remove biological contaminants (particularly bacteria and viruses) from the air.3,4,15,16 The widely used Standard 62.1 (Ventilation for Acceptable Indoor Air Quality) produced by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) requires use of an air filter with a minimum efficiency reporting value (MERV) not less than 6; this is intended to protect HVAC mechanical equipment from contamination with relatively large particles such as lint and dust.4,26

Most commercial buildings use filters ranging from MERV 5 to MERV 8, which provides building occupants with little protection from biological threats because this level of filtration does not effectively remove micron-sized particles from the air.4,27 It is not until MERV 13 or higher that particle removal in the size range of concern for biological threats begins to become significant (i.e., >90%).4 For example, Table 1 (below) shows the estimated filtration rates for 4 different biological agents for MERV 6, 8, 10, 13, 15, and 16 filters. As can be seen, at MERV 13 >95% of Bacillus anthracis organisms, the causative agent of anthrax, are removed from the air.3

| Table 1: Estimated Filtration Efficiency of Pathogen Removal for MERV-Rated Filters (%) a | |||||||

| Organism | Mean diameter (μm) | MERV 6 | MERV 8 | MERV 10 | MERV 13 | MERV 15 | MERV 16 |

| Bacillus anthracis | 1.118 | 15.5 | 36.7 | 39.2 | 96.3 | 99.9+ | 99.9+ |

| TB bacilli | 0.637 | 7.4 | 18.1 | 19.5 | 78.6 | 98.0 | 98.1 |

| Smallpox virus | 0.224 | 3.7 | 7.4 | 7.9 | 39.6 | 68.0 | 70.6 |

| Influenza A Virus | 0.098 | 6.2 | 11.2 | 12.0 | 46.2 | 71.0 | 76.0 |

Source: Adapted from Kowalski WJ, Bahnfleth WJ. Immune Building Technology and bioterrorism defense. HPAC Engineering 2003(Jan):57-62. Available at http://www.engr.psu.edu/ae/iec/publications/articles/immune_building_tech.pdf.

aBased on models of MERV test results from two filter manufacturers

Improper installation and/or maintenance of filtration systems: Filters are frequently installed improperly and/or improperly maintained, resulting in filter bypass, which reduces filtration efficiency.15,16, 28 One study that assessed filtration effectiveness in 57 commercial buildings located in 5 cities (Atlanta, GA; Birmingham, AL; Gainesville, FL; San Francisco, CA; and Washington, DC) found that “[n]one of the buildings . . . exhibited what could be considered “good” or “thorough” filter seal in all systems.”16 The Environmental Protection Agency’s (EPA) Building Assessment Survey and Evaluation (BASE) Study, which was conducted over a five-year period from 1994-1998 to characterize determinants of indoor air quality and occupant perceptions in 100 randomly selected public and commercial office buildings in 37 cities in 25 states, found that among the buildings assessed, 44% of the study space air handling units had fair or poor general conditions (i.e., state of filter and filter rack frames), 23% had fair or poor filter fit into frames, and 47% had filters in fair or poor condition.29

Infiltration: Infiltration reduces the effectiveness of air filtration systems because air that enters a building via infiltration bypasses filtration systems.15 Available evidence indicates that most commercial buildings are leaky relative to homes and that newer buildings are not more airtight than older buildings.15, 30,31 A “reasonable first order assumption for a typical leaky commercial building” is that the infiltration rate is equal to the air intake rate at the air handler.15 The filtration efficiency in such a situation would be greatly reduced. Measurements in commercial buildings indicate that windows and doors account for a relatively small amount of air leakage (~10-20%).15 Most leakage appears to occur between wall sections, wall-floor connections, corners, and the roof-wall interface.

Accessible air intake: Many commercial buildings have outdoor air intakes located at or near ground level, which increases the risk of occupant exposure to both intentional threats (bioterrorism), because of the air intake’s accessibility, and naturally occurring threats, because of the air intake’s proximity to potential contamination sources such as streets, alleys, parking lots, loading docks, and standing water.3,15,32 EPA’s BASE study found that among the buildings assessed, 14% of the study space air handling units had air intakes located at ground level.33

Reducing Risks

Reducing the Risk of Occupant Exposure to Biological Threats

Security Upgrades: Physical security upgrades can prevent access to the HVAC system and other vulnerable building components, thus minimizing the opportunity for a deliberate internal release of a biological agent. Risk also may be reduced through adoption of new technologies, changes to buildings and building systems, and improved operational strategies, which include the following:

- Ventilation system shutdown: Quickly shutting down a ventilation system to reduce occupant exposure after a release.

- Outdoor air purge (dilution ventilation): Bringing 100% outdoor air into a building, circulating it, and purging it to the environment to dilute and remove contaminants from the air after a release.

- Commissioning (and re-commissioning): Assessing a building’s ventilation system operation to ensure that it is operating in line with design intent.

- Envelope tightening: Increasing a building envelope's air tightness to reduce the movement of air contaminants into a building via infiltration.

- Pressurization: Over-pressurizing a building interior relative to outdoors to reduce the movement of air contaminants into a building via infiltration.

- Enhancing filtration efficiency: Improving air filtration efficiency to increase removal of particulate matter from the air.

- Isolating the air intake: Locating the air intake to reduce accessibility (e.g., high elevation).

- Isolating special-use spaces: Maintaining common use spaces considered vulnerable to internal releases (e.g., lobbies, mail rooms, auditoriums) at a lower pressure relative to adjacent spaces to limit potential spread of a biological agent beyond the immediate release area.1,3,4,15, 28, 31,34,35

Applicability of protective mechanisms: Not all protective mechanisms are applicable to all building attack scenarios. Of note, proper use of ventilation system shutdown and outdoor air purge depends on the specific characteristics of a building and its HVAC system and the agent that has been released. If applied improperly, these techniques may increase exposure instead of reducing it (Table 1).15

| Table 1: General Applicability of Protective Mechanisms for Risk Reduction in Four Attack Scenarios* | ||||

| Building Attack Scenario | ||||

| Protective Mechanism |

Large-Scale |

Air Intake |

Internal Release: |

Internal Release: |

| Ventilation System Shutdown |

+/- |

+/- |

+/- |

+/- |

| Outdoor Air Purge |

+/- |

+/- |

+/- |

+/- |

| Commissioninga |

+ |

+ |

+ |

+ |

| Envelope Tighteningb |

+ |

N/A |

N/A |

N/A |

| Pressurizationb |

+ |

N/A |

N/A |

N/A |

| Enhancing Filtration Efficiencyc |

+ |

+ |

+d |

+e |

| Isolating Air Intake |

N/A |

+ |

N/A |

N/A |

| Isolating Special-Use Spaces |

N/A |

N/A |

N/A |

+f |

*The extent to which any risk reduction measure will be protective is building specific and situationally dependent.

+/- Potential to increase exposure following a biological attack

N/A: Not applicable

a Is protective to the extent that it improves the reliability of HVAC system in support of other protective mechanisms; protective capacity is limited to design intent.

b Requires effective air filtration.

c Must address infiltration and filter bypass to realize full effectiveness

d Extent to which the distribution and spread of a biological agent can be reduced by filtration under this scenario depends, in part, on the HVAC system design and the point of entry of the agent.

e Will not protect the people present in the release area under this scenario, but it can reduce further exposures by reducing the distribution and spread of a biological agent beyond the release area as a result of its entry into HVAC system through the return air system (if present).

f Will not protect the people present in the release area under this scenario, but it can reduce further exposures by reducing the distribution and spread of a biological agent beyond the release area as a result of airflows created by pressure relationships that exist within different parts of the building relative to each other.

Source: Adapted from Persily, A. et. al. Building Retrofits to Protect Against Airborne Chemical and Biological Releases (NISTIR 7379). Washington DC: National Institute of Standards and Technology. March 2007. Available at https://www.nist.gov/publications/building-retrofits-increased-protection-against-airborne-chemical-and-biological.

Comparison of protective mechanisms: Each protective mechanism has its strengths and weaknesses, which should be taken into account when considering their implementation (Table 2).

| Table 2: Comparison of Protective Mechanisms for Risk Reduction | ||

| Protective Mechanism | Advantages | Disadvantages |

| Ventilation System Shutdown |

|

|

| Outdoor Air Purge |

|

|

| Commissioning |

|

|

| Envelope Tightening |

|

|

| Pressurization |

|

|

| Enhancing Filtration Efficiency |

|

|

| Isolating Air Intake |

|

|

| Isolating Special-Use Spaces |

|

|

Source: Adapted from Persily, A. et. al. Building Retrofits to Protect Against Airborne Chemical and Biological Releases (NISTIR 7379). Washington DC: National Institute of Standards and Technology. March 2007. Available at https://www.nist.gov/publications/building-retrofits-increased-protection-against-airborne-chemical-and-biological.

Expert Recommendations for Building Owners

Practical measures and available technologies to reduce risk: On June 13–14, 2005, the Center for Biosecurity of UPMC convened the Working Group on Reduction of Exposure to Infectious Agents during a Covert Bioterrorism Attack. The group was charged with recommending practical steps that building owners can take to reduce the risk of occupant exposure to biological agents following an aerosol release of a biological weapon.[1] The Working Group was composed of subject matter experts in air filtration, building ventilation and pressurization, air conditioning and air distribution, biosecurity, building design and operation, building decontamination and restoration, economics, medicine, public health, and public policy. With a focus on developing practical recommendations for improving or adjusting the functions of the heating, ventilation, and air conditioning (HVAC) systems in commercial and public buildings, the Working Group emphasized currently available technologies that would not be prohibitively expensive or require major retrofits, and that could provide additional benefits, such as improved indoor air quality.

A caveat: do no harm: Before implementing any measures intended to reduce the risk of exposure to occupants following a biological attack, it is imperative that building owners and operators fully assess the potential consequences of any risk reduction measures.[15,34 This includes understanding the specific building layout, activities (inside and out), and building systems and operations. Changes should not be made to buildings, building systems, and/or operations if they will degrade indoor air quality and comfort under normal operating conditions or if they will in any way interfere with the proper operation of fire protection and life safety systems.

Seven recommendations for immediate implementation: The following recommendations are based on the Working Group on Reduction of Exposure to Infectious Agents during a Covert Bioterrorism Attack and can be immediately implemented by building designers, owners, and operators as appropriate:

- Minimize filter bypass: Seal, caulk, and gasket everything (filter cartridge, retainer bank, tracking, etc.) to prevent filter bypass.1,15,28,35 The extent to which air filtration can reduce occupant exposure following a biological attack depends upon where the contaminant is released relative to the location of the filters and the occupants and the extent to which air flows through the filters.15 The efficiency of any filter can only be realized if the air actually enters the ventilation system and passes through the filter media. If infiltration is a problem and filter systems are not properly sealed, air will bypass the filters and efficiency will be reduced.

- Commission: Commission buildings during design and construction, and re-commission routinely to ensure that ventilation systems are operating in line with design intent.[1,15 The extent to which a building’s ventilation system can be relied upon to reduce occupant exposure following a biological attack depends, in part, on the extent to which the ventilation system is operating within its design intent. Commissioning and re-commissioning is necessary to ensure that the building can provide the intended level of protection.

- Enhance filtration efficiency: Increase air filtration to the maximum MERV level that is economically justifiable to improve the removal of particulate matter from the air.1,15,28,35]MERV 13 should be considered the minimal target MERV level because that is where particle removal in the size range of concern for biological threats becomes significant. For example, MERV 13 filters capture >90% of 1–3-micron particles entering the filter.26

If retrofitting, existing filters should be replaced with the highest MERV filters possible within design/economic constraints. If the ventilation system cannot accommodate at least MERV13 filters, upgrading the HVAC system should be considered. For new construction, buildings should be designed for the maximum MERV level that is economically justifiable.

Of note, the effectiveness of enhancing filtration efficiency can be greatly decreased by filter bypass, which can result from infiltration and/or poor air seal of filter installation.15 Accordingly, filter bypass issues must be addressed when enhancing filtration efficiency.1,15,28,35

When enhancing filtration efficiency, pre-filters should be utilized when reasonable, relative to contaminant load conditions, operating life cycle costs, and design/economic constraints.1,15,28,35 Pre-filtering is the use of lower MERV filters upstream of higher MERV filters to remove large particulate matter from the air before it reaches the higher MERV filters. Effective use of pre-filters can protect the performance and increase the life cycle of higher MERV filters, which can have positive economic benefits.28,35 In retrofit situations it may not be possible to incorporate pre-filters into the building’s ventilation system due to design constraints.15 However, if the ventilation system needs to be upgraded to accommodate enhanced filtration efficiency, then pre-filtration should be considered as a component of enhancing filtration efficiency.15 For new construction, pre-filtration should be considered as part of an overall strategy of maximizing filtration efficiency to the extent economically justifiable.

- Maintain HVAC systems: Ensure that the HVAC system functions properly by conducting regular inspections and performing proper maintenance.1,15,35

- Train staff: Ensure that maintenance staff has the appropriate training to operate and maintain the HVAC system.1,35

- Tighten envelope: Tighten the building envelope to reduce the infiltration rate when economically feasible.15,34,35 Of note, to be optimally effective in reducing potential exposures to biological threats, envelope tightening requires sufficient air filtration.15

If retrofitting, the impact of infiltration should be assessed and the building envelope tightened when economically feasible.15 For new construction, buildings should be designed and constructed to have a tight envelope.

Currently, there are no national standards for envelope tightness to guide the implementation of this recommendation. However, the ANSI/ASHRAE Standard 62.1-2007, Ventilation for Acceptable Indoor Air Quality and the ANSI/ASHRAE/IESNA Standard 90.1, Energy Standard for Buildings Except Low-Rise Residential Buildings by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) offer qualitative guidance on envelope tightening.

- Pressurize: Pressurize the building to reduce infiltration rate when economically feasible.15,31 Of note, to be optimally effective in reducing potential exposure to biological threats, pressurization requires sufficient air filtration.15

Whether a building can be pressurized depends upon the building’s geometry, HVAC system design, and envelope tightness, as well as weather conditions.15 Building pressurization requires that the HVAC system be able to deliver more air to the occupied space than is being exhausted and lost due to exfiltration.15,31 It may not be possible to pressurize a leaky building without first addressing envelope leakage.15

If retrofitting, the potential to achieve and maintain pressurization should be assessed, and the building should be pressurized when economically feasible.15 For new construction, buildings should be designed and constructed to achieve pressurization within design and economic constraints. There are currently no standard requirements established to guide the implementation of this recommendation and building pressurization strategies should be individually designed based on climate, building height, and envelope leakage.31

Costs and Benefits

Benefits and Costs of Implementing Risk Reduction Measures

Direct benefits: Implementing measures to reduce building vulnerability can reduce the risk of occupant exposure following a biological attack, which can have direct health and non-health benefits that, in turn, have potential economic benefits (Table 1, below)

| Table 1: Potential Benefits of Risk Reduction Measures | |||||

| Result of Risk Reduction Measures | Potential Health and Non-Health Benefits | Potential Economic Benefits | |||

| Reduced exposure to biological threats following an attack | • Reduced morbidity & mortality • Improved post-attack business continuity • Reduced decontamination costs • Reduced claims alleging harm • Reduced liability exposure • Increased insurability | • Reduced economic losses • Reduced litigation related costs • Reduced insurance premiums | |||

It is worth noting that implementing measures to reduce the risk of occupant exposure to biological threats can help reduce the likelihood of an attack.20 The October 2007 U.S. National Strategy for Homeland Security notes that “[t]errorist actors can be deterred and dissuaded from conducting attacks if they perceive that they are not likely to achieve their objectives or that the costs of their efforts are too high.”37 Hardening the built environment against biological attacks makes it more difficult to conduct a successful attack, which may discourage would-be terrorists.38

Collateral benefits: Available scientific data suggest that implementing risk reduction measures also can have collateral health and non-health benefits, including: improved energy efficiency, improved HVAC system cleanliness, and improved indoor air quality;[15] collateral benefits have potential associated economic benefits (Table 2, below).39

| Table 2: Potential Collateral Benefits of Risk Reduction Measures | ||

| Result of Risk Reduction Measures | Potential Health and Non-Health Benefits | Potential Economic Benefits |

| Improved energy efficiency | • Decreased energy consumption | • Reduced operating costs |

| Improved HVAC system cleanliness | • Decreased energy consumption • Reduced housekeeping costs | • Reduced operating/ maintenance costs |

| Improved indoor air quality (IAQ) | • Reduced IAQ complaints • Reduced employee turnover • Increased Productivity • Reduced health care costs • Reduced sick leave • Reduced claims alleging harm from poor IAQ | • Reduced operating/ maintenance costs • Increased occupancy and/or rent • Reduced litigation related costs |

Determining cost-effectiveness: While difficult to quantify, available evidence suggests that the collateral economic benefits of risk reduction measures may make them cost-effective and potentially cost-saving.21,40 The cost-effectiveness of such measures depends on several factors:

- Costs of implementation and maintenance (i.e., first costs, operating costs)

- Value of benefits derived from implementation (e.g., increased security, improved energy efficiency and HVAC system cleanliness, improved indoor air quality)

- Perspective of the analysis (e.g., building owner, employer, lessee).39

The value of the benefits derived from risk reduction measures are difficult to quantify and are building specific; therefore, the cost-effectiveness of hardening the built environment against biological threats is largely a value judgment, as there is no consensus determination of cost-effectiveness. However, measures that are found to be cost-saving would surely be considered cost-effective.

Costs and Cost-Effectiveness of Specific Measures

The costs of implementing risk reduction measures are building-specific and dependent upon the specific measures to be implemented, the unique features of the building (there is no typical building), and the extent to which ventilation system and building modifications are required (in retrofit situations).

Commissioning

Cost: The cost of commissioning (and re-commissioning) a building depends upon the size and complexity of the building and its ventilation system(s).15

One study on commissioning, by Mills, et al., analyzed results from 224 buildings in 21 states, representing 30.4 million square feet of commissioned floor area (73% existing buildings and 27% new construction).36 Results indicated that the median commissioning cost for existing buildings was $0.27 per ft2 (range $0.03 to $3.86 per ft2). The median commissioning cost for new construction was $1.00/ft2 or 0.6% of total construction costs (range $0.10 to $18.20 per ft2). A National Institute of Standards and Technology (NIST) case study estimated the cost of HVAC system testing, adjusting, and balancing (a commissioning cost) to be $0.63 per ft2 for the retrofit of an early 1960’s high rise office building to increase protection against airborne biological and chemical releases.15

- Cost-effectiveness: Building commissioning and re-commissioning can improve indoor air quality (IAQ) and energy efficiency.15 Mills and colleagues found a median whole-building energy savings of 15% (average 18%) for existing buildings and a corresponding payback time of 0.7 years.36 The median savings per building were approximately $45,000 ($2003); the average was $105,156 per building, but ranged as high as $1.8 million. The authors assessed that applying these results to the national commercial building stock could correspond to $18 billion in annual energy savings. For new construction, the study found a median payback time of 4.8 years. The authors concluded that “commissioning is one of the most cost-effective means of improving energy efficiency in commercial buildings. While not a panacea, it can play a major and strategically important role in achieving national energy savings goals . . .”36

Enhancing Filtration Efficiency

Cost: The cost of enhancing filtration is the sum of first costs and operating costs. First costs include equipment and installation (e.g., filters, design work when required), reconfiguration of filter racks (when required), modifications of air handling system fans, motors, electrical (when required). Operating costs are those associated with operating and maintaining enhanced filtration (e.g., filter replacement, maintenance, and increased electrical consumption, as when new filters require more powerful fans).15,28,35

First costs for enhancing filtration efficiency in retrofit situations are estimated to range from incidental to $2 to $3 per ft2.28 Operating costs for enhanced filtration efficiency are estimated at pennies to dollars per ft2.28

The NIST case study estimated the cost of retrofitting of the 1960’s high rise office building to increase filtration efficiency. Results indicated that upgrading from MERV 6 to MERV 11 (the highest efficiency filter that the building’s existing air handling unit could take) would cost $0.59 per ft2 and the annual operating costs for this retrofit would be $0.01 per ft2. Upgrading from MERV 6 to MERV 8 pre-filter, MERV 13 intermediate filter, and MERV 17 (HEPA) final filter would cost $2.47 per ft2 and that the annual operating costs for this retrofit would be $0.50 per ft2.15

Cost-effectiveness: While enhanced filtration can improve indoor air quality, energy efficiency, and HVAC system cleanliness, too few studies have been completed to generalize about its potential cost-effectiveness.15

However, modeling studies suggest that enhancing filtration efficiency could be cost-effective. One study estimated that the total costs of air filtration (e.g., filter costs, labor costs, energy costs) range from $0.70 to $1.80 per person/per month and concluded that these costs are “insignificant relative to salaries, rent, or health insurance costs.”41 Another study found that the cost of upgrading air filtration efficiency to high-efficiency filtration (i.e., >95% efficiency at 0.3 micron) in an office building cost $24 per person per year (cost includes filter purchase and increased energy costs).21 The author of that study estimated that if the improved filtration resulted in a 10% reduction in respiratory disease, a 1% increase in the productivity of workers who suffer from allergies, and 0.25% reduction in productivity losses associated with sick building syndrome, this could potentially result in an annual savings of roughly $220 per worker/per year.

Envelope Tightening

Cost: The cost for envelope tightening is not well established and would depend on the amount of air leakage in any particular building.15 Total costs for envelope tightening will include the costs of inspection and testing to determine air leakage sites, materials for sealing, labor, and construction staging costs.15

The NIST retrofit case study for the high rise office building estimated that sealing the building envelope would cost $5.21 per ft2.15 The authors note that their estimate focuses on “window and door sealing” and that “effective envelope tightening . . . is likely to involve the sealing of more leakage sites.”[5

Of note, to be optimally effective in reducing potential exposure to biological threats, envelope tightening requires sufficient air filtration.15

Cost-effectiveness: Envelope tightening can improve indoor air quality and energy efficiency.15 However, too few studies have been completed to generalize about the potential cost-effectiveness of envelope tightening.

One modeling study, based on a set of 25 buildings as a representative sample of the U.S. commercial building stock as of 1995, estimated that infiltration is responsible for about 15% of the total heating energy and 4% of the total cooling energy for U.S. office buildings.42 The results of the study indicated that tightening building envelopes by 25% to 50% could result in potential energy savings on the order of 26% for heating load and 15% for cooling load.

Pressurization

Cost: The cost of building pressurization is not well established and depends on various factors.[15] The primary cost arises from increased operating costs associated with increased energy consumption resulting from the heating and cooling of additional outdoor air brought into a building to pressurize it.15 The energy cost of pressurization is a function of the volume of outdoor air brought into a building and climate. The volume of air necessary to pressurize a building is in turn determined, in part, by the tightness of the building envelope. In

There also can be first costs associated with building pressurization, including ventilation system modifications and increased heating and cooling capacity.15

Of note, to be optimally effective in reducing potential exposure to biological threats, pressurization requires sufficient air filtration.15 general, it takes less outdoor air to pressurize a tight building.15

- Cost-effectiveness: Building pressurization can improve indoor air quality.15 Once again, though, too few studies have been completed to generalize about the potential cost-effectiveness of pressurization.

Building Pressurization

Building pressurization refers to the air pressure relationships that exist between the inside of a building relative to the outside of a building across the building envelope; it also refers to the pressure relationships that exist within different parts of a building relative to each other.15,17 Building pressurization is used to limit infiltration, which can lead to indoor air quality problems because air that enters a building via infiltration bypasses the air handling systems and can introduce contaminants into a building and contribute to moisture problems.[5,31 Pressurization also can be used to control the movement of air contaminants within a building.15,31

Maintaining positive air pressure relative to outside air prevents contaminants in the outside air from entering a building by means of infiltration.15,31 Such an approach could reduce the risk of exposure to biological agents from a large-scale outdoor release, provided that air entering the building through the HVAC system is sufficiently filtered to remove contaminants. Whether a building can be pressurized depends upon the building’s geometry, HVAC system design, and envelope tightness as well as weather conditions. Building pressurization requires that the HVAC system be able to deliver more air to the occupied space than is being exhausted and lost due to exfiltration. It may not be possible to pressurize a leaky building without first addressing envelope leakage.

Maintaining positive air pressure in one zone of a building relative to another can limit the distribution of an aerosolized biological agent released within that building by means of airflows created by pressure relationships that exist within different parts of the building relative to each other.15,31 Such an approach can be used to isolate special-use spaces such as lobbies, parking garages, and mail rooms that may be more vulnerable to an internal release by maintaining them at negative pressure relative to adjacent parts of the building.

For more information see:

- Persily A. Building Ventilation and Pressurization as a Security Tool. ASHRAE Journal 2004;46(9):18–24.

- Persily, A. et. al. Building Retrofits to Protect Against Airborne Chemical and Biological Releases (NISTIR 7379). Washington DC: National Institute of Standards and Technology. March 2007.

Decontamination Costs

Buildings contaminated in a biological attack would likely require some level of decontamination, the cost of which would depend on the type and extent of contamination and the method(s) required to decontaminate the building and certify it for re-occupancy.52

While the actual costs for decontamination in any given event would be situationally dependent, the experience following the 2001 anthrax attack through the Unites States Postal System are instructive. In October 2001, Bacillus anthracis spores were sent through the U.S. mail to news media companies and to U.S. Congressional offices, resulting in 22 cases of anthrax (11 inhalational and 11 cutaneous) and 5 deaths.53 Numerous sites were contaminated with B. anthracis spores as a result of direct contact with the spore laden letters or as a result of secondary or cross contamination.52,53 Where contamination was limited, surface treatments with liquid agents (e.g., bleach) were sufficient. In sites where contamination was significant, fumigation was required. Buildings that required fumigation were closed for months or years, and the costs of fumigation efforts ranged from $464 thousand to $200 million.52

Note: In an article published in February 2012, authors Schmitt and Zacchia arrive at a total cost of $320 million for decontamination following the anthrax letter attacks of 2001. See Ketra Schmitt and Nicholas A. Zacchia Total Decontamination Cost of the Anthrax Letter Attacks. Biosecurity and Bioterrorism: Biodefense Strategy, Practice, and Science. e-publication ahead of print. http://online.liebertpub.com/doi/full/10.1089/bsp.2010.0053. Accessed February 16, 2012.

For more information, see: U.S. Environmental Protection Agency, National Homeland Security Research Center (NHSRC):

- Decontamination & Consequence Management for information on NHSRC’s decontamination and consequence management research efforts, which focus on the rapid and cost-effective remediation and restoration of buildings and broad outdoor areas.

- Technology Testing & Evaluation for information on NHSRC’s evaluation efforts to provide reliable information regarding the performance of commercially available technologies that may have application for homeland security including Fumigant Decontamination Technologies.

NIST Case Study

Building Retrofits for Increased Protection against Airborne Chemical and Biological Releases

In March 2007, the National Institute of Standards and Technology (NIST) released improved guidance on retrofitting buildings to increase protection against chemical and biological attacks.[15] Intended for building owners, managers, engineers, and other decision makers, the report includes:

- a technical evaluation of the protective effects of 14 retrofit options using building airflow and contaminant transport modeling in 3 buildings. Each was subjected to computer-simulated generic particle and gaseous releases to determine the reduction in occupant exposure following the various retrofits;

- case studies in which specific retrofit options were investigated for 2 buildings: a high-rise office building with central air-handling systems and a one-story office building with multiple rooftop air handling units. These included development of pre-installation designs and cost estimates; and

- guidance on the application and effectiveness of the retrofits studied.

The authors note that the information presented “must be considered in the context of a specific building’s characteristics, including layout, system type and design, and occupancy [and that the] level of protection in a given situation is highly dependent on these characteristics and the nature of the contaminant release.”15 The authors also stress that while “it is extremely difficult to make general statements about what [retrofit] strategies will be effective in a given situation and to what degree . . . .better protection is a worthy goal, even if the degree of protection cannot be characterized in general terms.”15

In conjunction with the report, NIST also developed an economic analysis tool for use in selecting cost-effective approaches to mitigating chemical and biological attacks. The Life-Cycle Cost Analysis Tool for Chem/Bio Protection of Buildings can help building owners and managers make consistent comparisons of chemical and biological protection strategies based on established economic evaluation practices.

HVAC System Basics

To fully appreciate building occupants’ risk of exposure to airborne biological threats and what can be done to reduce it, it is necessary to understand how air enters and moves through buildings.

Ventilation

Building ventilation is the process of bringing outdoor air into a building, circulating it, and later purging it to the environment.17 The main purpose of ventilation is to provide acceptable indoor air quality by diluting and removing contaminants from the indoor air.17,18 Building ventilation is achieved by natural or mechanical means, or by a combination of the two.18

Natural ventilation: Natural ventilation is the use of differences in air pressure that exist between the inside of a building relative to the outside of it, across the building envelope, to ventilate a building.18,19 These air pressure differences are created by natural forces such as wind and temperature. Air moves into and out of naturally ventilated buildings through windows, doors, vents and other openings incorporated into the building design and via infiltration/exfiltration.

Mechanical ventilation: Mechanical ventilation is the use of mechanical air handling systems—commonly referred to as heating, ventilation, and air conditioning (HVAC) systems—to ventilate buildings.17,18 Most commercial buildings use mechanical ventilation, which is more controllable and responsive than natural ventilation in providing adequate indoor air quality. However, mechanical ventilation also can exacerbate infiltration/exfiltration, which can compromise indoor air quality.

Purpose, Design Basics, and Function of HVAC Systems

Purpose: An HVAC system provides adequate indoor air quality by: conditioning the air in the occupied space of a building in order to provide for the comfort of its occupants; diluting and removing contaminants from indoor air through ventilation; and providing proper building pressurization.[17]

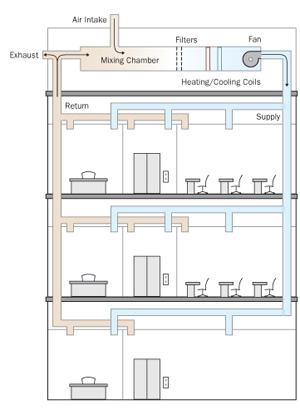

Design: While there are many different HVAC system designs and operational approaches to achieving proper system functionality, and every building is unique in its design and operation, HVAC systems generally share a few basic design elements (figure 1):

- Outside air intake

- Air handling unit—a system of fans, heating and cooling coils, air-flow control dampers, air filters, etc.

- Air distribution system

- Air exhaust system.17

Function: In general, outside (“supply”) air is drawn into a building’s HVAC system through the air intake by the air handling unit (AHU). Once in the system, supply air is filtered to remove particulate matter (mold, allergens, dust), heated or cooled, and then circulated throughout the building via the air distribution system, which is typically a system of supply ducts and registers.17

In many buildings, the air distribution system also includes a return air system so that conditioned supply air is returned to the AHU (“return air”) where it is mixed with supply air, re-filtered, re-conditioned, and re-circulated throughout the building. This is usually accomplished by drawing air from the occupied space and returning it to the AHU by: (1) ducted returns, wherein air is collected from each room or zone using return air devices in the ceiling or walls that are directly connected by ductwork to the air-handling unit; or (2) plenum returns, wherein air is collected from several rooms or zones through return air devices that empty into the negatively pressurized ceiling plenum (the space between the drop ceiling and the real ceiling); the air is then returned to the air-handling unit by ductwork or structural conduits.1,17

Finally, some portion of the air within is exhausted from the building. The air exhaust system might be directly connected to the AHU and/or may stand-alone.

Sample HVAC System.

Building Pressurization

Building pressurization refers to the air pressure relationships that exist between the inside of a building relative to the outside of a building across the building envelope; it also refers to the pressure relationships that exist within different parts of a building relative to each other.15,17 Building pressurization is used to limit infiltration, which can lead to indoor air quality problems because air that enters a building via infiltration bypasses the air handling systems and can introduce contaminants into a building and contribute to moisture problems.15,31 Pressurization also can be used to control the movement of air contaminants within a building.15,31

Maintaining positive air pressure relative to outside air prevents contaminants in the outside air from entering a building by means of infiltration.15,31 Such an approach could reduce the risk of exposure to biological agents from a large-scale outdoor release, provided that air entering the building through the HVAC system is sufficiently filtered to remove contaminants. Whether a building can be pressurized depends upon the building’s geometry, HVAC system design, and envelope tightness as well as weather conditions. Building pressurization requires that the HVAC system be able to deliver more air to the occupied space than is being exhausted and lost due to exfiltration. It may not be possible to pressurize a leaky building without first addressing envelope leakage.

Maintaining positive air pressure in one zone of a building relative to another can limit the distribution of an aerosolized biological agent released within that building by means of airflows created by pressure relationships that exist within different parts of the building relative to each other.[15,31] Such an approach can be used to isolate special-use spaces such as lobbies, parking garages, and mail rooms that may be more vulnerable to an internal release by maintaining them at negative pressure relative to adjacent parts of the building.

For more information see:

- Persily A. Building Ventilation and Pressurization as a Security Tool. ASHRAE Journal 2004;46(9):18–24.

- Persily, A. et. al. Building Retrofits to Protect Against Airborne Chemical and Biological Releases (NISTIR 7379). Washington DC: National Institute of Standards and Technology. March 2007.

Minimum Efficiency Reporting Value (MERV)

MERV is a measure used to describe the efficiency with which particulate filters remove particles of a specified size from an air stream.54 The higher the MERV designation, the better the efficiency of removal, particularly for smaller particles (Table 1). MERV levels 1 through 16 are determined using the ANSI/ASHRAE Standard 52.2-2007 test method by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE).54 Standard 52.2-2007 does not address high efficiency particulate air (HEPA) filters or ultra low penetration air (ULPA) filters (MERV 17 – 20). HEPA/ULPA filters are assigned MERVs based on their performance in accordance with standards published by the Institute of Environmental Sciences and Technology (IEST).51

| Table 1: MERV Parameters | |||||

| Composite Average Particle Size Removal Efficiency (%) in Size Range (μm) - ANSI/ASHRAE Standard 52.2-2007 | Contaminants Typically Controlled | Typical Applications | |||

| MERV | 0.3–1.0 | 1.0–3.0 | 3.0–10.0 | ||

| 1 | — | — | <20 | Particles >10.0 μm: pollens, dust mites, textile/carpet fibers | Minimum filtration; residential buildings |

| 2 | — | — | <20 | ||

| 3 | — | — | <20 | ||

| 4 | — | — | <20 | ||

| 5 | — | — | 20–35 | Particles 3 - 10.0 μm: mold, spores, cement dust | Most commercial and better residential buildings |

| 6* | — | — | 35–50 | ||

| 7 | — | — | 50–70 | ||

| 8 | — | — | >70 | ||

| 9 | — | <50 | >85 | Particles 1.0 - 3.0 μm: Legionella, lead dust, coal dust, auto emissions | Superior residential and better commercial buildings |

| 10 | — | 50–65 | >85 | ||

| 11 | — | 65–80 | >85 | ||

| 12 | — | >80 | >90 | ||

| 13 | <75 | >90 | >90 | Particles 0.3 - 1.0 μm: all bacteria, most tobacco smoke, droplet nuclei, most smoke | Hospital inpatient and general surgery; superior commercial buildings |

| 14 | 75–85 | >90 | >90 | ||

| 15 | 85–95 | >90 | >90 | ||

| 16 | >95 | >95 | >95 | ||

|

IEST Standards |

|||||

| 17 | >99.97 on 0.30 μm particles, IEST Type A | Particles <0.3 μm (viruses, radon progeny, carbon dust) | Cleanrooms and pharmaceutical manufacturing | ||

| 18 | >99.99 on 0.30 μm particles, IEST Type C | ||||

| 19 | >99.999 on 0.30 μm particles, IEST Type D | ||||

| 20 | >99.9999 on 0.10–0.20 μm particles, IEST Type F | ||||

* Minimum requirement under ASHRAE standard 62.1 (Ventilation for Acceptable Indoor Air Quality). Source: Adapted with permission from ANSI/ASHRAE Standard 52.2-2007: Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size. Atlanta, GA: American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc. 2007 © American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc., www.ashrae.org

For more information see:

- Guidance for Filtration and Air-Cleaning Systems to Protect Building Environments from Airborne Chemical, Biological, or Radiological Attacks (April 2003)

- Risk Management Guidance for Health, Safety and Environmental Security under Extraordinary Incidents. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (January 2003)

- Kowalski, W, Bahnfleth, W. Airborne-microbe filtration in indoor environments. HPAC Engineering 74(1); 2002: 57-69.

Frequently Asked Questions (FAQs)

Would sensor technologies help to reduce the risk of occupant exposure following an attack with a biological weapon?

Sensors to identify the release of a biological agent could be helpful in alerting building operators of an attack so that preventive measures such as a ventilation system shutdown or outdoor air purge could be taken.15 As noted in the section on Reducing Risk, both of these responses to a biological attack require timely situational awareness—building operators need to know when and where an attack has occurred to implement the proper response. Absent actionable situational awareness, implementation of either of these measures has the potential to increase exposure rather than decrease it if implemented at the wrong time.15

To be effective in reducing exposure to either a chemical or biological agent following an attack, sensors must be fast (i.e., real-time), cost effective, and able to detect a large number of threat agents.[15 While there is a lot of research and development ongoing in sensor technology, to our knowledge, currently available sensor technologies are not mature, robust, or cost-effective enough to warrant implementation in commercial buildings at this time; this is especially true for biological threats.15,43,44

For more information, see:

- Sensor Systems for Biological Agent Attacks: Protecting Buildings and Military Bases by the National Research Council, National Academies of Science (2005).

- Protecting Building Occupants and Operators from Biological and Chemical Airborne Threats by the National Research Council, National Academies of Science (2007).

- Building Retrofits to Protect Against Airborne Chemical and Biological Releases (NISTIR 7379) by the National Institute of Standards and Technology (March 2007).

Are new technologies available that would reduce the risk of occupant exposure following an attack with a& biological weapon?

New technologies for protecting building inhabitants from biological (and chemical) attacks include ultraviolet germicidal irradiation (UVGI) and photocatalytic oxidation air cleaning (PCO).15

UVGI systems use ultraviolet light (UV) to kill or deactivate microorganisms and have been used in healthcare facilities for years. They are usually installed in ductwork or in upper portions of rooms with shielding.15,45 More recently, UVGI systems have begun to be used in buildings to keep ventilation system components clean, improve indoor air quality, and address biosecurity concerns.3,15

PCO systems remove bioaerosols and chemicals from the air by flowing the air past a photocatalyst that is irradiated by UV light.15,46 A photocatalyst is a chemical compound that becomes highly reactive when exposed to various wavelengths of UV light, such as titanium dioxide. This process creates highly reactive molecules (e.g., hydroxyl radicals) that combine and react with airborne contaminants, breaking them down into carbon dioxide and water. PCO devices are commercially available.

The Center for Biosecurity’s Working Group on Reduction of Exposure to Infectious Agents during a Covert Bioterrorism Attack (Working Group) did not make any recommendations about the use of new technologies, primarily because they have yet to be independently evaluated using standardized methods, and there was no consensus regarding their performance characteristics.1 The Working Group encouraged the purchase of new technologies only after they have been validated and thoroughly field tested, especially if an existing technology produces comparable results. A 2007 report from NIST regarding building retrofits to increase protection against chemical and biological attacks concluded that more performance data or technology development is needed before general application of these technologies.15

| Table 1. Comparison of New Technologies for Risk Reduction | ||

| Technology | Advantages | Disadvantages |

| UVGI | • Offers protection against biological agents • Low pressure drop • Potential for improved IAQ • Potential for improved ventilation system efficiency over time | • No standard test method for determining effectiveness • No design and installations guidance currently available |

| PCO | • Offers protection against biological agents • Low pressure drop • Potential for improved IAQ • Potential for improved ventilation system efficiency over time | • No standard test method for determining effectiveness • No design and instillation guidance currently available • No standard method to determine if catalyst has become ineffective by exposure to airborne substances • Potential to produce harmful chemical byproducts unclear |

Source: Adapted from Persily, A. et al. Building Retrofits to Protect Against Airborne Chemical and Biological Releases (NISTIR 7379). Washington DC; National Institute of Standards and Technology. March 2007. Available at https://www.nist.gov/publications/building-retrofits-increased-protection-against-airborne-chemical-and-biological.

For more information, see:

- Building Retrofits to Protect Against Airborne Chemical and Biological Releases (NISTIR 7379)

by the National Institute of Standards and Technology (March 2007). - U.S. Environmental Protection Agency, National Homeland Security Research Center (NHSRC), Technology Testing & Evaluation, HVAC In-Duct UV Light Systems.

Should building owners and operators be concerned about the threat from chemical weapons?

The Center for Biosecurity focuses its efforts on reducing the threat posed by biological weapons, which in our view are the only weapons capable of presenting a strategic threat to the United States on par with nuclear weapons. That said, the threat from chemical weapons should not be overlooked. Several states potentially hostile to the United States are suspected of having chemical weapons programs, and there are groups, such as al-Qa’ida, that are committed to attacking the U.S. and are also pursuing chemical weapons capabilities.2,47 Available information suggests that the threat of chemical terrorism—particularly small-scale attacks—is increasing.47 According to the July 2007 U.S. National Intelligence Estimate regarding the terrorist threat to the U.S. homeland, al-Qa’ida “would not hesitate” to use chemical weapons “if it develops what it deems is sufficient capability.”2

Information about chemical devices, recipes, and dissemination methods are easily accessible on the Internet.47 Military grade chemical weapons (e.g., sarin, VX) in the wrong hands pose a serious threat, but it can be argued that the larger threat is from toxic industrial chemicals (TICs), such as cyanide, chlorine, and pesticides. These are more readily available and potentially can be used to contaminate food and water supplies or crudely delivered using an explosive device.47

Buildings are attractive targets for chemical attacks as they pose the potential for wide-scale agent dispersal through the air handling system, which can cause mass casualties and high economic costs. It is known that al-Qa’ida is aware of the potential to use building air handling systems to attack building occupants; training in Afghanistan-based al-Qa’ida camps as early as 1998 included the use of ventilation systems as a "delivery system" to attack buildings with poisons.5

Technologies are available that can help protect building occupants from chemical threats. Sorption-based gaseous air cleaning technologies are used to remove gaseous contaminants from the air.15,46 While not widely used in commercial buildings, such systems are used in some manufacturing facilities, for example, to control odors and/or exposure to corrosive or undesirable gases.

Sorption-based gas air cleaning systems remove contaminants from the air by physical adsorption or chemisorption.[15,46 Physical adsorption is based on the attractive forces between the sorbent (e.g., activated carbon, silica gel, alumna) and the gas molecules in the air and is a reversible process. Chemisorption is based on chemical reactions between the adsorbent (e.g., potassium permanganate, phosphoric acid, copper, silver salts, zinc oxide) and the gas molecules in the air. No single sorbent or adsorbent is able to remove all potential chemical attack agents from the air, and a combination is needed to offer wide-ranging protection.

Adding sorption-based gas air cleaning systems to commercial buildings would likely be expensive; expenses include both first costs (air cleaning system, additional space for system, design work, ventilation system modifications) and operating costs (media replacement and increased electrical consumption as a result of increase pressure drop associated with system).15

Gas phase cleaning systems are associated with a larger pressure drop than particle filtration systems, and, thus are generally more expensive to operate.15 In addition, the larger pressure drops associated with gas phase cleaning may require significant ventilation system modifications in retrofit situations, which also are expensive.

A NIST case study estimated that upgrading a 1960's high-rise office building from MERV 6 filters to MERV 8 pre-filters, MERV 13 intermediate filters, MERV 17 (HEPA) filters, AZDM-TEDA grade carbon gas phase filters, and MERV 11 final filters would cost $9.26 per ft2, and that the annual operating costs for such a system would be $1.87 per ft2.15

The corresponding retrofit without gas phase filtration—upgrading from MERV 6 filters to MERV 8 pre-filters, MERV 13 intermediate filters, and MERV 17 (HEPA) final filters—would cost $2.47 per ft2, and the annual operating costs for this retrofit would be $0.50 per ft2.15 The additional cost to add gas phase filtration to the retrofit was $6.79 per ft2, and the additional operating cost was $1.37 per ft2.

| Table 2: Advantages and Disadvantages of Sorption-based Gaseous Air Cleaning Technology | ||

| Technology | Advantages | Disadvantages |

| Sorption-Based Gaseous Air Cleaning | • Offers protection against chemical agents • Potential for improved IAQ | • High pressure drop • No standard test method for determining effectiveness • Additional design guidance needed |

Source: Adapted from Persily, A. et al. Building Retrofits to Protect Against Airborne Chemical and Biological Releases (NISTIR 7379). Washington DC; National Institute of Standards and Technology. March 2007. Available at https://www.nist.gov/publications/building-retrofits-increased-protection-against-airborne-chemical-and-biological.

For more information, see:

- Building Retrofits to Protect Against Airborne Chemical and Biological Releases (NISTIR 7379) by the National Institute of Standards and Technology (March 2007).

- Guidance for Filtration and Air-Cleaning Systems to Protect Building Environments from Airborne Chemical, Biological, or Radiological Attacks by the U.S. Department of Health and Human Services, National Institute for Occupational Safety and Health (April 2003).

Should building owners and operators be concerned about the threat from radioactive materials?

As noted above, the Center for Biosecurity focuses its efforts on reducing the threat posed by biological weapons, which, in our view, are the only weapons capable of presenting a strategic threat to the U.S. on par with nuclear weapons. That said, the threat from radioactive materials should not be overlooked. There are groups, such as al-Qa’ida, that are committed to attacking the U.S. and are also pursuing nuclear/radiological weapons capabilities.2 According to the July 2007 U.S. National Intelligence Estimate regarding the terrorist threat to the U.S. homeland, al-Qa’ida “would not hesitate” to use “radiological or nuclear material in attacks . . . if it develops what it deems is sufficient capability.”2

Radioactive materials can be dispersed by detonating a nuclear weapon, attacking a fixed nuclear facility, or by employing a radiological dispersal device (RDD).35,48 An RDD is “any device that causes the purposeful dissemination of radioactive material without a nuclear detonation.”48 The type of RDD most commonly discussed is the dirty bomb—a conventional explosive used to disperse radioactive material. However, radioactive materials also can be dispersed by non-explosive means, such as depositing them in food or water or aerosolizing them. Aerosolized radioactive materials, regardless of the source, are a threat to building occupants because they can potentially be introduced into a mechanically ventilated building in the same ways as described for biological agents.

While air filters and air-cleaning devices will not stop the radiation emitted from a radioactive material, they can remove the radioactive materials from the air, which can reduce potential exposures following a release.35

For more information, see:

- Guidance for Filtration and Air-Cleaning Systems to Protect Building Environments from Airborne Chemical, Biological, or Radiological Attacks by the U.S. Department of Health and Human Services, National Institute for Occupational Safety and Health (April 2003).

- Radiation Event Medical Management from the U.S. Department of Health and Human Services.

Will implementing threat reduction measures earn me any LEED points?

Implementing the biological threat reduction measures recommended by the Center for Biosecurity’s Working Group on Reduction of Exposure to Infectious Agents during a Covert Bioterrorism Attack can potentially help building owners earn credits under the U.S. Green Building Council’s (USGBC) Leadership in Energy and Environmental Design (LEED) Green Building Rating System™. For example, LEED points can be earned for commissioning, staff education, building system maintenance and monitoring, envelope tightening, and improving indoor air quality through measures such as enhancing air filtration to MERV 13 or better.49,50

For more information, see:

- U.S. Green Building Council (USGBC), Leadership in Energy and Environmental Design (LEED) Green Building Rating System™.

- National Institute of Building Sciences (NIBS), Whole Building Design Guide, Balancing Security/Safety and Sustainability Objectives and LEED®-DoD Antiterrorism Standards Tool.

References

- Hitchcock PJ, Mair M, Inglesby TV, et al. Improving performance of HVAC systems to reduce exposure to aerosolized infectious agents in buildings; recommendations to reduce risks posed by biological attacks. Biosecur Bioterror. 2006; 4(1):41-54. https://www.liebertpub.com/doi/pdfplus/10.1089/bsp.2006.4.41. Accessed May 7, 2014.

- Office of the Director of National Intelligence. National Intelligence Estimate: The Terrorist Threat to the US Homeland. Washington, DC: Office of the Director of National Intelligence; July 2007. https://nsarchive2.gwu.edu//nukevault/ebb270/18.pdf. Accessed November 28, 2007.

- Kowalski, W. and W. Bahnfleth. Immune building technology and bioterrorism defense. HPAC Engineering 2003;75(1): 57-62. http://www.aerobiologicalengineering.com/ibbd.pdf. Accessed November 28, 2007.

- American Society of Heating, Refrigerating and Air-Conditioning Engineers. Report of Presidential Ad Hoc Committee for Building Health and Safety under Extraordinary Incidents on: Risk Management Guidance for Health, Safety, and Environmental Security under Extraordinary Incidents. Atlanta: American Society of Heating, Refrigerating and Air-Conditioning Engineers; January 26, 2003. https://www.ashrae.org/File%20Library/Technical%20Resources/Resiliance%20Activities/2003716113740_347.pdf. Accessed November 28, 2007.

- Lichtblau E, Meyer J. Response to terror; the investigation; jihad training details heighten attack fears; tactics: in disclosures to FBI, imprisoned Bin Laden associate describes lessons in chemical weapons, explosives and other acts of terror. Los Angeles Times. September 28, 2001; Part A; Part 1; National Desk: pg. 22.

- U.S. Environmental Protection Agency. An introduction to indoor air quality - Biological Pollutants. Washington, DC: U.S. Environmental Protection Agency; November 14, 2007. https://www.epa.gov/indoor-air-quality-iaq/introduction-indoor-air-quality. Accessed November 28, 2007.

- Myatt, TA, Milton, DK. Indoor pollutants: endotoxins. In: Spengler JD, Samet JM, McCarthy JF, eds. Indoor Air Quality Handbook. New York: McGraw-Hill; 2001: 42.1–42.14.

- Platts-Mills, TA. Indoor pollutants: allergens derived from arthropods and domestic animals. In: Spengler JD, Samet JM, McCarthy JF, eds. Indoor Air Quality Handbook. New York: McGraw-Hill; 2001: 43.1–43.15.

- Muilenberg, ML. Indoor pollutants: pollen in indoor air: sources, exposures, and health effects. In: Spengler JD, Samet JM, McCarthy JF, eds. Indoor Air Quality Handbook. New York: McGraw-Hill; 2001: 44.1–44.18.

- Burge, HA. Indoor pollutants: the fungi. In: Spengler JD, Samet JM, McCarthy JF, eds. Indoor Air Quality Handbook. New York: McGraw-Hill; 2001: 45.1–45.33.

- Rao, CY. Indoor pollutants: toxigenic fungi in the indoor environment. In: Spengler JD, Samet JM, McCarthy JF, eds. Indoor Air Quality Handbook. New York: McGraw-Hill; 2001: 46.1–46.19.

- Nardell, EA. Indoor pollutants: Tuberculosis. In: Spengler JD, Samet JM, McCarthy JF, eds. Indoor Air Quality Handbook. New York: McGraw-Hill; 2001: 47.1–47.13.